Plastic molds are tools used with plastic molding machines in the plastic processing industry, and can provide complete structural configurations and precise dimensions for plastic products. According to different molding methods, plastic molds can be divided into different types.

1. Injection mold

Injection molds are often used to produce thermoplastic parts, and the corresponding processing equipment is injection molding machines. The manufacturing process is as follows: first put the plastic into the injection molding machine, heat and melt it through the heating cylinder at the bottom, and then push the screw or column of the injection molding machine through the nozzle of the injection molding machine and the pouring system of the mold to finally cool the plastic. It hardens to form, and then the product is demolded.

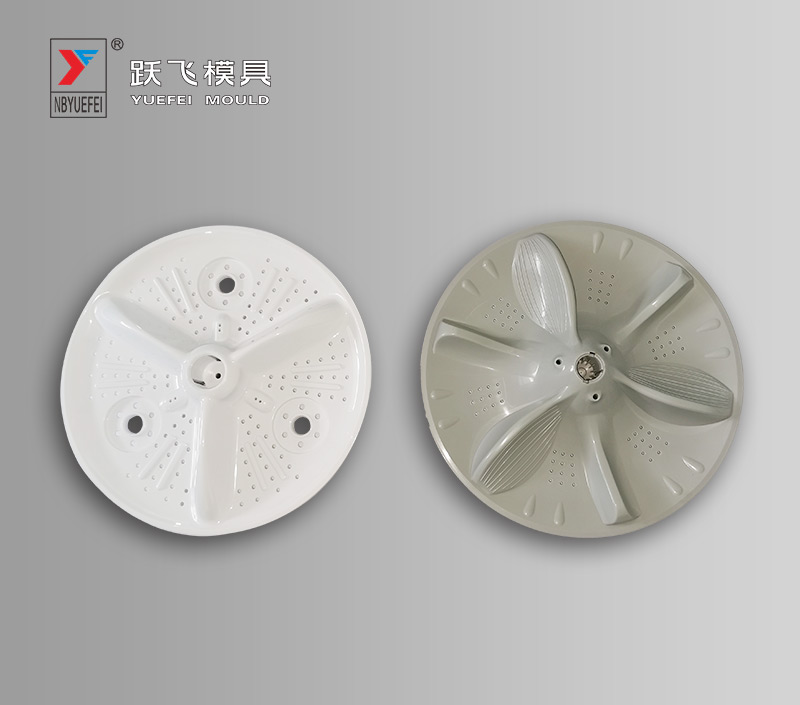

The structure of an injection mold is usually composed of molding parts, pouring system, guide parts, push-out mechanism, temperature adjustment system, exhaust system, supporting parts and other parts, and its overall structure is made of plastic mold steel. The injection molding process is usually suitable for the production of thermoplastic products, and the plastic products produced by the injection molding process are widely used. Daily necessities, complex electrical appliances, auto parts, etc. are all made by injection molds, so people often say that injection molds are in the production of plastic products. The most widely used processing method.

2. Blow mold

Blow molds are molds used to form hollow plastic containers, such as beverage bottles, daily chemicals and other packaging containers. According to the process principle, the main forms of blow molding include extrusion blow molding hollow molding, injection blow molding hollow molding, injection stretch blow molding hollow molding, multilayer blow molding hollow molding, sheet blow molding hollow molding, etc. The corresponding equipment for blow molding of hollow products is usually called a plastic blow molding machine. In addition, blow molding is only suitable for the production of thermoplastic products, and its structure is relatively simple, and the materials used are mostly made of carbon.

3. Compression mold

Compression molds include two mold structure types, namely compression molding and injection molding, which are mainly used for thermosetting plastic molding. The corresponding supporting equipment is a pressure molding machine. Among them, the compression molding is mainly composed of a cavity, a feeding cavity, a guiding mechanism, an ejection part, a heating system, etc. According to the characteristics of the plastic, the compression molding method heats the mold to the molding temperature, usually 103°-108°, puts the compression molding powder into the cavity and the feed cavity, and then closes the mold to allow the plastic to soften under high temperature and pressure. After a certain period of time, it will be solidified and formed into the desired product shape. The difference between injection molding and compression molding is that there is no separate feeding chamber for injection molding. Injection molds are widely used and are often used for packaging electrical components.

www.3g265.com

English

English 簡體中文

簡體中文 Espa?ol

Espa?ol Deutsche

Deutsche